Introduction

Not

suitable for wearing without finishing the raw fabric. So raw fabrics/garments

need a different kind of finishing.

The woven fabric finishing process

The

cotton fabrics woven in its loom-state not only contain impurities with warp

size but also require further treatment to develop its full textile potential.

Furthermore, it can get substantial additional value by applying one or more

finishing processes.

Desizing process

The

process of removing sized elements from warp yarn after the textile fabric is called

desizing. The desizing agent determines what is involved with the impregnation

of the fabric with the agent in order to degrade or dissolve the size material

and ultimately allow the degraded products to be washed.

Scouring process

Scouring

is the process of removing natural (oil, wax, fat, glue, etc.) as well as impurities (during fabrication) to produce hydrophilic and clean textile

materials. This is a very important process of wet processing. In other words, Scouring

is a chemical washing process on a cotton cloth to remove natural wax and

non-fibrous impurities (e.g. seed fragments) from the fiber and any added soil

or dirt. Scouring is usually carried on iron vessels called kiers. The fabric

is boiled in an alkali, which forms a soap with free fatty acids (saponification).

Kier is usually closed, so a solution of sodium hydroxide can be boiled under

pressure by excluding oxygen which reduces the cellulose of the fiber.

Bleaching process

Bleaching

is a process in which the natural colors of textile fibers are removed in order

to achieve a white color for the development of the actual color. It improves

whiteness by removing natural color and remaining trace impurities from cotton;

the degree of bleaching required is determined by the required whiteness and

absorption.

Mercerizing process

Mercerization

is the treatment of cellulose fabrics and yarns, mainly cotton and textile

finishing for discipline, which improves dyes and reduces tear strength fabric

shrinkage, and provides a silky shine. The process was developed by John Mercer

in 1844, who applied a 55-65 ° Twaddle scale (20-30%) sodium hydroxide solution

for cotton washing. Here cotton is treated with sodium hydroxide. Cellulose is

converted to hydrate. A caustic soda concentration of 20-26% is used. Effective

mercerization requires the use of wetting agents.

Singeing process

In the textile industry, loose fibers scattered on the surface of textile

materials are equipped removed them. When done on cotton fabrics, it results

in reduced durability, better dyeing properties, improved reflection, no frosty

appearance, a smoother surface, more precision in printing, improved visibility

of fabric structure, less peeling, and reduced pollution resulting in fluff and

debris removal. The process usually allows the fibers stretched over a flame of

gas to ignite on either side of the fabric on one or both sides. Cellulose

fibers such as cotton are easily singed because the extensible fibers are

burned in light ash which is easily removed. Thermoplastic fibers are harder to

singe because they melt and form hard residues on the fabric surface.

Raising process

Is

raising another finishing process. During emergence, the fabric surface is

treated with sharp teeth to lift the surface fibers, resulting in hairiness,

softness, and warmth, such as a flannel.

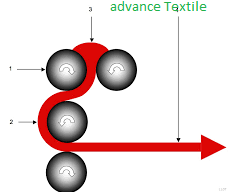

Calendaring process

Calendaring

of textiles is a finishing process used to smooth, coat, and smooth any

material. With textiles, the fabric passes through calendar rollers at high

temperatures and pressures. Calendaring peacock-like fabrics are used to create

its aqueous effect and cambric and some types of satin. To prepare for calendaring,

the fabric is folded lengthwise through the front or face, and sewn along the

edges. The fabric can be folded together over the entire width, but not as

often as it is difficult. The fabric is then rolled through rollers that polish

the surface and make the fabric smoother and more lustrous. High temperatures

and pressures are used as well. The fabrics that go through the calendaring

process look thin, glossy, and papery.

|

| Calendering process |

Sanforizing process

Sanforization

is a process that is mainly applied to cotton fabrics and textiles made from

natural or synthetic fibers. It is seen after washing that the woven fabric is

a method of stretching, shrinking, and fixing in both length and width before

cutting and reducing the fabric shrinkage. The cloth is continuously fed into a

Sanforizing machine and moistened with water or steam. Fabrics and articles

made from it may be labeled as a certain shrink-proof value, for example, below

1%.

Dyeing process

Dyeing

is the process of applying dyes or pigments to textile materials such as fibers,

yarns, and fabrics in order to achieve the desired color. Dyeing is usually

done in a special solution containing dyes and certain chemical elements.

Pigment molecules are fixed with fibers by binding as factors controlling

absorption, expansion, or temperature, and time. The bond between the dye

molecule and the fiber can be hard or weak depending on the dye used. Cotton is

colored with a variety of dyes, including VAT dyes and modern synthetic

reactive and direct dyes.

Printing process

Textile

printing is the process of applying fabric dye to specific patterns or designs the

color of properly printed fabrics is bound with fiber, to prevent washing and

abrasion. Textile printing is related to dyeing but in the case of proper

dyeing, the whole fabric is evenly covered with one color, whereas in printing

one or more colors are applied only to specific parts and to sharply defined

patterns. In printing, wooden blocks, stencils, engraved plates, rollers, or silkscreens

can be used to color fabrics. The colors used in printing are thickened by the

capillary attraction to spread the color beyond the boundaries of any pattern

or design.

|

| Printing process |

Conclusion

Energy

consumption in the form of water and electricity is relatively high, especially

in processes such as washing, de-sizing, bleaching, rinsing, dyeing, printing,

coating, and finishing. In the textile industry, the main part of the water is

used for the wet processing of textiles. About 25 percent of the total textile

production energy is used in dyeing such as fiber production, spinning,

twisting, weaving, weaving, garment manufacturing, etc. About 34 percent of

energy is spent on spinning, 23 percent on weaving, 38 percent on chemical wet

processing, and five percent on miscellaneous processes. Electricity in

rotation and weaving predominates in consumer patterns, on the other hand, thermal energy is the main reason for chemical wet processing.

0 Comments