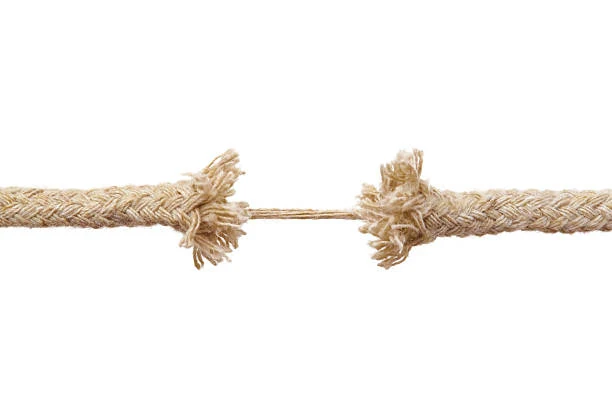

Tearing

Tearing strength

Another

method of measuring tear strength is the ballistic tear test, which measures

energy loss during tearing. ASTM 1424 describes a tear strength test using the

Elmendorf tear tester. The relationship between tearing force and energy loss

has the following equations:

Energy

loss = Tearing force x Distance

Tearing strength testing different standards

Items The main standards

i.

Pendulum method ISO 9290, ASTM D 1424,

DIN 53862, DIN EN ISO 13937.1. KS-K 0535, EN ISO 13937.1, etc.

ii.

Tongue method ASTM D 2261.DIN 53859.1.DIN EN

13937.4.NF G 07-146, NFG 07-148, NFG 07-149, KS K 0536.EN ISO 13937.4, etc.

iii.

Trapezoidal method ASTM D 5587.DIN 53859.5.KSK 0537,

etc.

iv.

Another Methods BS 4303(Wing Method).

DIN 53859.2(Rectangular method). DIN EN ISO 13937.2(Trouser method). DIN EN ISO

13937.3(Wing Method). NFG 07-145(Nail method).NF G 07-147 (Nail method).NF ISO

13937.3(Wing Method). EN ISO 13937.2(Trouser method) etc.

Now, due to the different test methods available to measure the strength of the fabric from different angles, we had to calculate the following factors considering the compression, extension, and weak areas of the fabric which affect the tensile / tear test result-

i. Grab or strip test method related: a number of tests, gauge length, extension rate, jaw or grip, jaw fracture within 5 millimeters of the jaw mouth, etc.

ii. Regarding tear test method: Geometry of test piece, nature of separation, yarn properties, fabric structure, yarn sliding, jamming, density, test speed, fiber used in yarn construction, etc.

iii. Bursting test method related: to stretch, yarn alignment, fabric making, etc.

Kothari V. K clarified that the mechanical and comfort-related properties of the fabric are related to the linear density, twist level, thread density, crimp levels of warp and weft, cover factor, fabric thickness, and structural properties of fabric skew and bow. It is no doubt that the strength of the fabric depends directly on the strength of the yarn. Other issues related to the variation in the properties of yarns, especially those made with natural fibers, are stapled length, fiber fineness, fiber strength, twist quantity, evenness, fiber length variation, fiber finishing, drafting, and doubling in spun yarn spinning, chemical treatment like sizing, thick and thin places, slubs, neps, and so on. It is easy to calculate yarn strength using both a single yarn strength tester and a Lea tester. However, since the Lea strength tester is affected by the frictional force present during the test and is not sensitive to the weak point of the individual yarn, and does not represent multiple strengths of a single thread, it does not serve any purpose from the next point processing result. We only need to consider the results of the single-thread test here.

Factors affecting the tearing strength

The

factors affecting the tearing strength are as follows:

a.

The GSM of the fabric indicates the tear strength. Higher GSM means more

tearing power.

b.

The strength of the yarn is directly related to the tearing strength of the

fabric. More yarn strength means more tear strength.

c.

Weave designs mean plain weave may have the lowest tear strength. Similarly, spun yarn has less tear strength than the filament yarn.

d.

The knitted fabric is less strong than the woven fabric.

e.

A tearing strength tester is a suitable tool for measuring the tear resistance

of various materials including textiles and fabrics.

How to improve tearing strength

a.

Since the fabric has a core problem, there is no specific remedy to improve it.

b.

Marginal improvements may be possible through washing or some treatment.

c.

Tear strength is a property that cannot be improved once a fabric is made.

Longer fiber lengths and higher twisted yarns may result in higher tear

strength characteristics for future production.

d.

By reducing the number of threads on the opposite side of a test, the strength

of the tear can be increased.

e.

Use yarn with a high breaking load in the direction of the test to increase the

strength of the tear.

f.

Reduce friction between yarns to increase the strength of the tear test.

g.

Use a good quality fabric softener.

Sample

preparation

i.

At first, we take a sample of 100 × 75.

ii.

The template is placed on the sample and cut according to the template.

iii.

A slit was made in the middle of the sample, with a range of 20 mm.

iv.

In the experiment, Elmendorf continuously tore the fabric to a distance of 43

mm from the end of the slit to the opposite end.

v.

The pendulum lever principle is used here.

Test

procedure:

i.

The instrument has a sector-shaped pendulum that carries a running sample clamp

and a fixed clamp on the frame.

ii.

When the pendulum is raised to the starting position, the sample is transferred

between the two clamps.

iii. A tear begins by cutting a slit in the sample between the clamps.

iv.

The pendant is then released and the specimen is torn off as a moving clamp,

moving away from the stationary clamp.

v.

The pointer is attached to the pendulum, which graduates directly to the

tearing force reading.

0 Comments