Shedding mechanism

The

term shedding refers to the act of creating a shed. Shedding is the process of

making an open path across the warp yarn and through it, some warp threads are

raised by their harness, and others leaving down. When the shed is open, the

filling yarn is inserted. The shed is changed as determined by the pattern. A

shading device is a device used to raise or open a shed. Creating isolation is

called raising or opening the shed, while the opposite is known as lowering or

closing the shed. The type of machine used to raise and lower the shed is

different from the type of loom. The shades are raised and lowered by rotating

the tablets or cards with the help of a tablet loom. Sheds are made by

harnesses in a floor loom. Among the ink looms is another primitive shedding

device, which has a set of heddles, and the shed is made by hand.

Originally

there were no sheds, and like the work of tapestry weaving, the threads of the

warp were individually sorted and inserted into it. After each weft thread was

woven the warp threads had to be picked up and lifted again, which slowed down

the process? To speed up the process, a variety of devices were developed to

create a reproducible shed so that the weft could pass between isolated

threads, and so the threads did not have to be separated individually each

time. The first type of shedding device is called a shed rod. It is a rod that

is inserted into the rail to make weaving easier and came at the same time as

the heddles. The threads on the top and bottom of the rod were changed

periodically and the threads going to the bottom of the rod went through the

string heddles attached to a bar. The shed is made in two ways: by raising the

shed-rod and lifting the heddles.

The shedding mechanism divides the warp threads into two sheets by lifting some of the heald shafts and lowering the others. Since each warp yarn from the weaver's beam passes through one eye of the heald shaft, while some held shafts are lifted and lowered by a shedding mechanism, the corresponding warp edges are raised or lowered thus forming an opening. When this happens, a shed is created and the next initial process, “picking”, can begin. A shed can be created by a variety of shedding mechanisms such as crank, tappet, dobby, and jacquard. The minimum number of heald shafts for shed formation is two. When the number of handle shafts being used is more than two, whether a shaft is lifted or lowered is determined by the weaving structure of the fabric woven into the particular loom.

Types of shedding mechanism

There

are three types of shedding mechanisms. These are-

i.

Tappet shedding

ii.

Dobby shedding

iii.

Jacquard shedding

Tappet shedding

Tappet

shedding uses a tappet and cam to control movement up and down the heald shaft.

Tappet shedding is the easiest shedding motion. It can control 8 heald shafts.

Plain weaving, plain twill, and plain satin and sateen weave can be produced

using tappet shedding. An important type of cam is the one that provides a

rotating motion for the object to produce reciprocating motion in the levers

and rods by the sliding contract. When the rod has to take a series of lifts,

rest breaks and thus creates a shed known as tappet shedding. Tappet shading

has the simplest design capabilities compared to other shadings. It is one of

the most expensive textile looms. The weaving speed of tappet shedding is

comparatively much higher than others. The tappet is usually placed under the

loom during the weaving process. The maximum number of heald shafts in tappet

shedding is fourteen. Tappet shedding produces comparatively more than dobby

and jacquard shedding. Production costs are also very low here.

Opportunities for tappet shedding

i.

Tappet shading uses tappets and cam to control movement up and down the heald

shaft.

ii.

It is the easiest shading motion.

iii.

It can control 8 heald shafts.

iv.

Plain weaving, plain twill, and plain satin and sateen weave can be produced

using tappet shedding.

v.

It has the least versatile shedding motion.

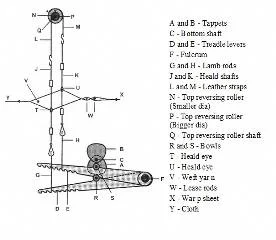

Tappet shedding mechanism (Negative)

Construction

The

figure shows a negative tappet shedding mechanism. A pair of A and B tappets

are fixed 180 degrees to each other in the bottom shaft C. The two treadle

levers D and E are connected to the loom back-rail by a bracket F. The bracket

acts as a complement to the lever. The lamb rod has teeth to carry G and H,

respectively, in two steps. The two held shafts J and K are connected to the

lamb rod. A top reverse roller shaft Q carries two rollers of different

diameters. The small diameter N roller is attached to the leather strap L with

which the front heald shaft J is attached. The large diameter roller P is

attached to the leather strap M with which the rear heald shaft is attached.

Tappets A and B touch the anti-friction bowl or followers R and S, respectively,

which are fixed to the treadle lever. The heald shafts have heald eyes by T and

U through which the warp thread passes X is the warp sheet and the Y is the

cloth. Odd ends pass through one heald shaft while even ends pass through

another heald shaft.

Working Principle

i.

When the bottom shaft is rotated clockwise, the tappets are also rotated. The

tappet will disappoint the anti-friction bowl and treadle.

ii.

With a fulcrum at one end, the front of the treadle goes down. This action is

transferred to the lamb rod, the heald shaft, and the leather strap.

iii.

Thus, a heald shaft is lowered and the threads attached to this heald shaft are

lowered and form the bottom layer of the shed.

iv.

The leather straps attached to the inverted rollers are attached in the

opposite direction, as when the leather strap is pulled down; it is unwound

from the roller.

v.

Therefore, the shaft continues to rotate clockwise and the other leather strap

is wound on its roller. The heald shaft is raised and therefore the lamb rod

and treadle lever are also raised.

vi

Threads attached to the heald shaft are also raised and form the upper layer of

the shed.

vii.

For the next shed, the other tappet works with other bowls, treadles, lamb

rods, heald shafts, straps, and rollers, and the other heald shaft is lowered.

viii.

The first heald shaft is raised by inverted rollers and thus the positions of

the heald shaft are exchanged.

ix.

Thus, for one rotation of the bottom shaft, two shades are formed.

x.

In this type of tappet shedding, therefore, a tappet depresses the

corresponding treadle and lowers the corresponding heald shaft. But the other

heald shaft is raised by inverted rollers. Thus, this type of shedding

mechanism is known as the negative tappet shedding mechanism.

Dobby shedding

Dobby

is a shading device that is placed on top of a loom to create an illustrated

pattern using a greater number of healds than the capacity of the tappet. Infancy weaving, dobby is used to create small figures with warp threads and

healds, while jacquard is used to create very large and elaborate figures with

warp threads and hooks, needles, and harness cords.

Opportunities for dobby shedding

The

opportunities for dobby shedding in the textile industry are as follows-

i.

In the cotton industry, a maximum of 24 shaft dobbies is used. But mostly 16 to

20 shafts are used.

ii.

In the worsted industry, dobbies with 36 jacks are used and many of them are

suitable for positive and heavy shedding.

iii.

Fabric, a dobby loom pattern can be easily made while in the case of tappet, it is

laborious and expensive.

iv.

Dobby shedding offers better facilities for producing a variety of patterns

than is possible with a larger number of held tapes.

v.

Dobby shedding is widely used for twill, satin, and other common weaves.

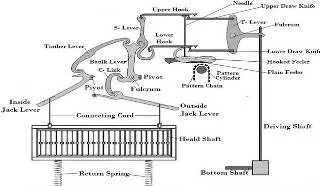

Dobby shedding mechanism (Negative)

i.When

the connecting rod moves up and down and the T-lever gives external and

internal movement. According to the fabric design, when the peg comes in

contact with the feeder, the right part of the filler is raised and the left

part is lowered. The hooks are lowered because the hooks are supported by a

filler.

ii.

When the left edge of the filler is bent the upper hook comes in contact with

the upper knife. In this case, when the connecting rod goes down, the upper

part of the T-levers gives external movement. As a result, the upper part of

the S-lever, the bulk lever, also moves to the right. Thus, tension is

created between the wooden lever and the link.

iii.

As the outer and inner jack levers are connected to the wooden lever and the

link, the lever moves upwards at the same time. Therefore, the heald shaft has

risen.

iv.

Similarly, when the left edge of the filler is bent, the bottom hook comes in

contact with the bottom knife. In this case, the rod moves upwards when connecting

and the lower part of the T-lever moves to the right. As a result, the lower

part of the S-lever moves to the right and the same process occurs i.e. the

upper part of the bulk lever moves to the right. Here, the jack lever is moved

at the same time.

v.

Therefore, the heald shaft rises again. Thus, a heald shaft is a rise by the

lower knife and the upper knife. Therefore, the shaft will be lowered with the

help of a return spring and will remain below for further selection.

Jacquard shedding

The

Jacquard is a shedding device that is attached to the top of the handloom or to

the power loom and controls a large number of warp threads to create the most

varied sheds for fabric decoration. This process is probably one of the most

important weaving innovations because jacquard shedding has made possible the

automatic production of an unlimited variety of intricate pattern weaving.

Opportunities for Jacquard Shedding

Jacquard

shedding points out various opportunities for shading below:

i.

Each warp yarn can be handled differently at any pick.

ii.

Harness is used to lowering or lifting the warp yarn during weaving.

iii.

No heald frames are used in jacquard sheds or shedding.

iv.

Sophisticated or large or elaborate designs are used for jacquard design.

v.

One warp yarn for each harness cord.

vi.

Minimum figuring capacity is 100s- means minimum. The number of warp

repetitions is less than 100.

vii.

The maximum figuring power is over the 1800s + and the maximum number of warp

repetitions is over the 1800s.

viii.

Using a jacquard shedding, the most expensive fabrics are made.

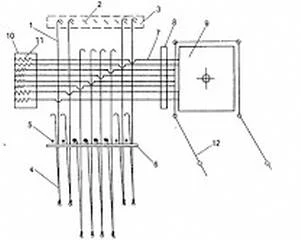

Jacquard shedding mechanism

The

basic principle of the jacquard shed or shedding mechanism is described below

with the help of a single lift single-cylinder jacquard. Punch cards are used

for jacquard sheds made according to the design. Here, a pattern card is used

for single picking with these pattern cords. A pattern chain is created that

takes place in the pattern cylinder. Here, the pattern card hole indicates the

design warp up. Knives from giraffes that are all tied together. They are moved

down and up from the loom crankshaft. The pattern cards of the perforated

cylinder are pressed against the needle as the giraffe begins to move upwards. If

there is a hole in the pattern cad, the needle just opposite the hole will go

through it and the hole will need a cylinder and a knife if this needle is

attached and forming a line at the top of the jacquard shed or shedding. It

will press the hook and lift the knife if the pattern card is blank opposite

the needle. As a result, the hook is left down. This way any pick of the

Jacquard 408 hook and can be lifted from the bottom line of the Jacquard shed

or shedding.

0 Comments