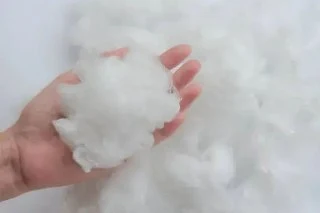

Polyester fiber

Polyester

fiber occupies a leading position among all chemical fibers. The unique

properties of these fibers are due to the presence of aliphatic and aromatic

moieties in the macromolecular chain and regular molecular structure. Polyethylene

terephthalate (PET) is the main polyester used for fiber production, not only

because of its good end-use properties and economy of production but

especially because of the ease of physical and chemical modification, negative

suppression, and positive enhancement properties. Although PET and modified PET

fibers have been extensively investigated, there is still no fully described

phenomenon to predict mechanical behavior and tensile failure based on

structure or manufacturing parameters. One of the main reasons is the complex

nature of changes during fiber production and changes in structure during the

influence of pressure fields, temperature, time, and environmental factors.

Properties of polyester

The properties of polyester are as below-

A. Physical properties of polyester

i. Tenacity: Tenacity is the term that is used to

measure the strength of fiber/yarn. It is usually defined as the ultimate or

breaking force of the fiber (in gram-force units) divided by the linear density

(denier). The tenacity of Polyester is 5-7 gm/den.

ii. Elongation at break: Elongation at break is also known as

fracture strain. It is the ratio between the changed length after breaking the

test specimen and the initial length. It expresses the fiber's ability to

resist shape change without forming cracks. Elongation at the break of polyester is

15 – 30%.

iii. Elastic modulus: The modulus of elasticity, or Young's

modulus, is an essential property of polymers. It is the ratio of stress to

elastic strain and it depends on temperature and strain rate. The elastic modulus of

polyester is 90.

iv. Elasticity: Most of today's polyester fibers are

composed of terephthalic acid and ethylene glycol. Yarns and fabrics made from

this type of polyester are strong and very elastic.

v. Moisture Regain (MR %): It has only 0.4% moisture regain at 65%

RH which causes static electrical charges to easily build up.

vi. Specific Gravity: Specific Gravity is the ratio of the

density of a substance at a given temperature to the density of an equal volume

of water at the same temperature. The Specific Gravity of polyester is 1.38.

You Also May Know: Fashion industry overview

vii. Melting point: Polyesters have a high melt temperature

(250–265°C).

viii. Volumetric Swelling: None

ix. Ability to protest

friction: The ability to

protest friction of polyester is excellent.

x. Color: White

xi. Light reflection

ability: It is very good.

xii. Lusture: The luster of polyester is bright.

B. Chemical properties of Polyester

i. Effect of Acids: Polyester has good resistance to acids in

cold conditions. But polyester degrades by H2SO4 at high temperatures.

ii. Effects of Basic: Polyester has good resistance to basic in

cold conditions but strong NaOH dissolves polyester in boiling.

iii. Effect of bleaching: Polyester does not affect by the bleaching processes like H2O2 or Chlorine bleach.

iv. Organic solvent: Organic solvent does not affect polyester.

v. Protection ability

against mildew: Good

vi. Protection ability

against insects: Good

vii. Affinity to Dyes: Polyester could be dyed with dispersed,

azoic color, and some pigments.

viii. Solvents of

polyester: Following

are the solvents of polyester:

a. Chlorinated hydrocarbon,

b. CF3COOH

c. Phenol (in hot condition)

0 Comments