Textile industry in China

The

textile industry in China is the world's largest in terms of both overall

production and exports. China exported textiles worth $274 billion in 2013,

nearly seven times more than Bangladesh, the second largest exporter with $40

billion in exports. It accounts for 43.1% of global apparel exports. The

industry began to grow in the early 20th century until cotton yarn production

accounted for about 20% of China's total modern industrial output in that

century. Stimulated by WWI, the industry expanded rapidly until the Depression

in the thirties. The industry continued to grow more slowly until the Second

Sino-Japanese War when the war destroyed many mills and their supply chains.

They did not fully recover until the 1950s, during which time many of the big

tycoons moved their empires to Hong Kong to avoid persecution, while the rest

of the industry was monopolized by the government. After Deng Xiaoping came to

power, he identified these Hong Kong companies as models of technologically

advanced capitalist companies, and they were able to reconnect with companies

in mainland China.

China's textile industry history

The

textile industry has always been one of the most significant and enduring

technological pillar industries of ancient Chinese civilization. It can be

traced back to the time when the Chinese first developed sericulture and the

process of making silk.

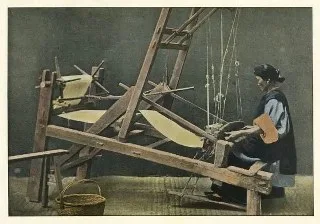

Between

the spring and Autumn Periods and the Warring States Period, the average person

had already mastered the art of spinning on a rudimentary loom. A spinning

machine with two crossbars, a knife, and a pounding knife. When a woman weaves,

one end of the warp is attached to a wooden post and the other end is wrapped

around the weaver's waist; hence, the device is also called the waist machine.

Later,

as weaving technology continued to advance, several other looms began to emerge

in ancient China. These include vertical looms, dingqiao looms, Luo looms, and

more. And the Hualou loom is the most technologically sophisticated. According

to historical sources, such looms, with their complex construction and strict

technical standards, first existed in the late Tang Dynasty; nevertheless,

their popularity did not peak until the Song Dynasty.

Edmund

Cartwright, a barber by trade, came up with the idea of the hydraulic loom in

1785. In the same year, Thales began using the steam engine as the driving

force for textile machines. This innovation met with immediate success and led

to a significant increase in the overall productivity of the weaving process.

In fact, they point out that the technological revolution of textile

modernization in Europe and the United States is somewhat less advanced than

the traditional textile technology used in China.

Initially,

all machines and accessories were imported from Britain or America. It

foreshadowed an industrial trend of importing technology and exporting

manufactured goods that characterized much of the 20th century. However, in the

1920s, Japan became a major supplier of machines, and some began to be made in

China as well, establishing a textile-machine-tool industry that would

eventually grow large enough to supply neighboring countries.

Although

the total capacity of Chinese mills exceeded that of Japanese in the 1930s, a

third of the cotton yarn and half of the cotton goods produced in China were

produced by Japanese-owned mills. Japanese mills had the advantage of advanced

technology and more capital, while Chinese mills were limited by management

inefficiency, lack of organization, and financial weakness. In particular,

Japanese mills were able to survive the Depression in the 1930s because they

had stronger and more stable financial backing.

In

1934, China's National Economic Council established the Cotton Industry

Commission, with the aim of improving the quality of Chinese raw cotton and

improving spinning, weaving, and dyeing techniques. However, due to the lack of

capital and high outstanding debt of Chinese mills, production costs were still

high. In 1936, Chinese mills began harvesting inland rather than coast in an

effort to have more competitive costs and prices. However, war suddenly broke

out and destroyed both the Chinese and Japanese textile industries.

In

July 1937, there were about 2.75 million spindles and 25,500 looms in Chinese

ownership. Japan controlled 2.38 million spindles and 33,800 looms. Dramatic

expansion plans were underway by both camps, but most were halted by the

outbreak of war. For comparison, the British controlled about 220,000 spindles

and 4,000 looms at that time.

After the defeat of Japan in 1945, the textile industry in China was dominated solely by the Chinese, giving China the possession of many well-equipped and efficient manufacturing units. However, Chinese management technical and management skills were limited. After the Japanese retreat, the Chinese government took over 40 mills and incorporated them into the Chinese Textile Industries Corporation (CTIC), arguing that government management would get the mills up and running again very quickly. The government wanted the mills to clothe the army and generate enough profit to reduce the government budget deficit. It wanted to capture markets previously supplied by Japan and organize mills to eliminate clothing shortages in China and thus capture the domestic textile market. Ultimately this resulted in the government controlling 50% of the textile industry in China. However, a real reason these mills were more efficient was that the Japanese maintained equipment in their mills well during the war. Yet despite the easy availability of capital, the government took no steps to expand its mills, indicating a lack of willingness to invest rather than a desire to make a profit.

The

textile industry provides one of the best contexts for exploring the long-term

modern development of China's social and industrial system. It constitutes an

engine of economic development in many countries in the early stages of

industrialization. From the nineteenth century to the Republican period

(1912–49) China developed modern textile factories (silk and cotton) while

traditional household handicraft production continued. After 1949, the

communist government nationalized or collectivized textile production and

invested relatively little in the sector under the "heavy industry

preference policy", but after the reform policy in 1978, the textile

industry became one of the main engines of economic growth and absorbed huge

labor. This process represents China's unique path of industrialization and

gradual transition from the traditional sector to the modern sector over the

long term, while it also illuminates the effects of institutional changes in

the socialist system since the 1950s through the reforms that began in 1978.

Long-term development of China's textile industry, with a special focus on

three issues such as labor, technology, and market. These indicators enable

China's industrialization to be measured by, for example, changes in social

structure, the impact of international technology transfer, and the impact of

institutional change.

China

introduced free competition in textiles in the early 1980s, leading to a

deregulated and decentralized textile industry. However, there are numerous

ways for the state to regulate the development of an industry without

prohibiting competition or private entry. Because the economic and social

importance of the industry is too great to ignore, the government protects its

market share and exercises guidance through macroeconomic instruments and

indirect support measures. Contrary to the conventional notion of a government

using its state-owned enterprises to advance its economic interests, China's

industrial policy also implies that the government works together with its most

private sectors to reach its national goals.

The textile industry has been important in Chinese exports since the introduction of economic

reforms in the 1970s, for example, representing 29.38% of the value of total

Chinese exports in 1994. However, textile and clothing exports declined to

25.5% as a percentage of total Chinese exports. In 1995, the textile and

clothing industry became an important foreign exchange earner in China. In 1995

these industries ranked second in export value, but together were the leading

net currency earners among Chinese exports.

In the framework of China's 1999 Go Out Policy, Chinese policymakers developed an additional program to enhance China's international competitiveness in the textile industry. The plan refers to the introduction of new systems and ancillary technologies. By 2000, the industry was making profits, and by 2004, 95 percent of Chinese textile firms were considered privately owned. Today the share of privately owned enterprises has even increased to 99 percent as only 359 Chinese textile and apparel manufacturing firms out of a total of 22,474 companies are state-owned.

Through this reform and opening-up approach, China hoped to eliminate export quotas in 2005, which had protected advanced industries for more than four decades.

Except for Lithuania, all member states supported the new quota agreement, which meant that half of the blocked garments would be released and enter Europe freely, while the other half would count against the Chinese textile quota for 2006.

As Jack McCann noted in 2011: "The Chinese government's strategy is to create a textile and apparel sector that no other nation can compete with."

As one trade expert noted: "Although China emphasizes high-tech (development), we have never said we will give up traditional industries." According to UNCTADstat statistics, the value of Chinese global textile exports increased from $138 billion to $320 billion between 2005 and 2017. Moreover, the production of textile products directly provided nearly 5 million jobs in 2017 (National Bureau of Statistics of China, 2018). Indirectly, the Chinese textile and apparel sector is estimated to provide more than 10 million Chinese jobs. Trade experts explain how employment, but also the fact that the textile industry is the basis of industries like machinery, is the main reason the government focuses on its development.

In China's 13th Five-Year Plan for the Textile Industry (2016–2020), the Chinese government again referred to the textile industry as a traditional pillar industry for the country but also recognized several issues such as weak innovation capacity, structural overcapacity, and lack of brand influence. To address these shortcomings, it calls for the development of high-tech- and new-generation fibers and industrial textile products.

Although the sector is not on its SEI's list, the Chinese government links this upgrading effort to China's more general Made in China 2020-2025 goal. While the plan emphasized the importance of a market-oriented approach and free competition, it aimed to promote brand-building and intelligent textile production and encourage enterprises to focus on research and development and quality creation to guide national textiles and Champion their foreign activities.

By 2023, Beijing wants to create 1 million textile jobs in Xinjiang. In 2017, there were already over 2700 registered textile companies in the area, employing around 350,000 local residents. Where the target of 1 million jobs has not yet been reached, new policy measures have been implemented to encourage the expansion of the sector.

0 Comments