Breathable fabric

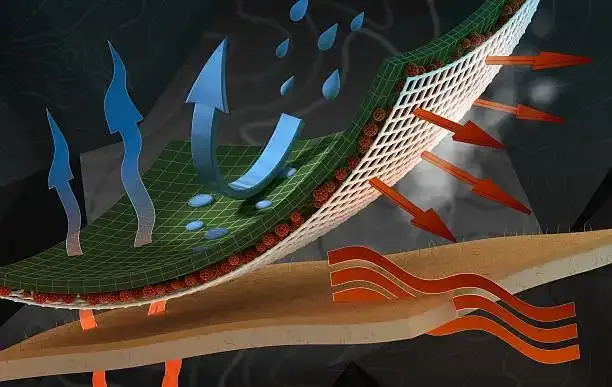

Breathable fabrics are the epitome of comfort and style. They allow air to flow through them, making them ideal for use in garments that are worn during hot weather conditions or strenuous activities. In recent years, breathable fabrics have become increasingly popular among designers and consumers alike due to their numerous benefits.

Breathability has become a critical factor in choosing quality textiles because people want clothing that feels comfortable while also providing excellent performance features; hence many brands now incorporate various types of sustainable textile options into their product lines - particularly those with eco-conscious values at heart.

The demand for breathable fabric only continues growing larger each day due to the increasing awareness around environmental sustainability and consumer preferences leaning towards products with a lasting value over cheap unsustainable alternatives. Consequently, designers must continue developing innovative ways of creating fashion pieces without compromising on breathability factors if they aim towards setting new trends within the industry while staying true to what matters most Quality.

How to test breathability of fabrics

Breathability is a critical property of fabrics that determines their ability to allow air and moisture to pass through. Testing the breathability of fabrics is essential in ensuring that they are suitable for various applications such as clothing, bedding, and upholstery. There are different methods used to test the breathability of fabrics. This essay will discuss some of these methods.

i. One common method used to test the breathability of fabrics is the water vapor transmission rate (WVTR) test. This method involves measuring the amount of water vapor that passes through a fabric sample over a specified period. The WVTR test uses a cup filled with distilled water, which is placed on top of the fabric sample mounted on a testing apparatus. The cup's weight before and after testing allows for the calculation of how much moisture passed through during the testing period.

ii. Another method commonly used to measure fabric breathability is air permeability testing. This method measures how much air can pass through a given area or volume section per time unit under specific conditions such as pressure or temperature differences between two surfaces in contact with each other.

iii. A third method often employed by experts when measuring fabric breathability entails placing small sensors on both sides of the material being tested while it undergoes movement tests simulating typical user activity like running or walking around town; from there data detailing its ability to allow perspiration evaporate away into surrounding atmosphere can be measured alongside rates at which heat escapes via convection currents created by said movements.

iv. Lastly, one may also use subjective tests where users wear garments made from different materials and compare their comfort levels based on variables like sweat buildup during exercise or feeling dampness against the skin from sweat accumulation throughout daily activities outside physical labor-intensive tasks requiring more robust protective gear.

Breathable fabric advantages

i. One of the primary advantages of breathable fabric is its ability to regulate body temperature. When we exert ourselves physically, our bodies generate heat which can make us feel uncomfortable and sweaty. Breathable materials like cotton and linen allow air to circulate through the fibers, wicking away moisture from our skin, thus keeping us cool even when we sweat.

ii. Another benefit of breathable fabric is its hypoallergenic nature. People who suffer from allergies or sensitive skin often find that synthetic materials exacerbate their symptoms by trapping allergens close to their skin. Natural fibers like bamboo or hemp provide a great alternative as they are less likely to cause irritation while still being highly absorbent.

iii. Furthermore, using breathable fabrics can help reduce environmental impact since these textiles tend to be made from natural sources such as wool or organic cotton which do not require harsh chemicals during production processes- unlike synthetic fabrics such as polyester which require petrochemicals for its creation.

Breathable fabric disadvantages

i. Moisture may not pass through the fabric quickly enough. When this happens, the trapped sweat will get wet from the inside. In dry environments, most breathable fabrics work well. In semi-humid environments, waterproof-breathable fabrics struggle. In very humid conditions, nothing is going to keep you dry.

ii. Outside humidity is too high. If the outside air is already almost saturated with water vapor, it can't absorb the extra vapor you generate. When you sweat, it stays next to the skin, unable to evaporate.

iii. Fabric may be wet or saturated with water. When this happens, usually due to the failure of a durable water-repellent finish, the outside humidity is essentially 100 percent. Moisture inside the fabric cannot pass through these saturated spots.

Conclusion

Breathable fabrics have become increasingly important in modern society due to increased demand for functional textiles that offer high-performance properties without compromising comfort levels associated with traditional materials such as cotton or wool fibers found in many everyday clothing items. Therefore, testing methods for fabric breathability are essential in ensuring that the garments we wear provide adequate protection from heat and moisture without sacrificing our comfort levels.

0 Comments