Fiber Definition

Fiber

is a natural or man-made material that is significantly longer than it is wide.

Fibers are often used to make other materials. Strong engineering elements

often attach fibers, for example, carbon fiber and ultra-high-molecular-weight

polyethylene.

Textile

Fiber

Textile

Fiber is a fiber that has some special characteristics such as staple length,

spun length, fineness, strength, twisting capacity, etc. are called Textile

fiber. Banana fiber is a fiber but not textile fiber because not fulfill that

characteristic.

Different

types of Textile Fibres are below-

1.

Animal Fibre: The fiber which we get from an animal such as sheep, or a goat

is called animal fiber. Animal fibers are commonly made from hair, fur, skin,

or silk (in the silkworms’ case). Examples- Wool, Silk, etc.

a.Wool

fiber: Wool refers to the hair of the domestic sheep or goat, which is

distinguished from other types of animal hair in that the individual strands

are coated with scales and tightly crimped, and the wool as a whole is coated

with a wax mixture named lanolin, which is waterproof and dirt proof. Woolen

refers to a bulkier yarn produced from carded, non-parallel fiber, while

worsted refers to a finer yarn spun from longer fibers that have been combed to

be parallel. Wool is commonly used for warm clothing. In Cashmere, Indian

Cashmere goat hair, and North African Angora goat hair Mohair are a type of

wool is known for its softness.

|

| Wool Fibre |

Other

animal fibers made from hair or wool are alpaca wool, vicuna wool, llama wool, and camel hair, commonly used in the production of coats, jackets, ponchos,

blankets, and other warm covers. Angora refers to the long, thick, soft hair of an

Angora rabbit. Qiviut is the fine inner wool of the muskox. Wadmal is a thick cloth

made of wool, produced in Scandinavia, often 1000 ~ 1500 CE.

b.

Silk fiber: Silk

is an animal fiber made from the fibers of the cocoon of the Chinese silkworm

which is spun into a smooth fabric prized for its softness. There are two main

types of silk: 'mulberry silk' produced by the Bombyx Mori, and 'wild silk'

such as Tussah silk (wild silk).

When

cultivated in habitats with fresh mulberry leaves for consumption, silkworm

larvae produce the first type, and the tussah silk silkworm is produced by

feeding on oak leaves. About a quarter of the world's silk production is made

up of agricultural silk. Sea silk is a very delicate, rare, and precious fabric

that is hidden from the silky filament or byssus by the foot glands of the pen

shell.

2.

Plant fiber: The

fibers which are we get from different types of trees are called plant fiber.

Examples: Cotton, flax, jute, hemp, sisal, etc.

a. Cotton

fiber: Cotton

is a flexible, fluffy staple fiber that grows in a ball or protective fields,

around the seeds of the cotton plant of the genus Gossypium in the Mallow

family Malvaceae. The fiber is almost pure cellulose. Under natural conditions,

cotton balls will scatter the seeds.

|

| Cotton Fibre |

The plant is a shrub native to tropical and subtropical regions of the world,

including the United States, Africa, Egypt, and India. The largest variety of

wild cotton species is found in Mexico that is followed by Australia and

Africa. Cotton was raised independently in the old and new worlds.

The current estimate of world production is about 25 million tons or 110 million

bales per year, which is 2.5% of the world's arable land. India is the world's

largest cotton producer and the United States has been the largest exporter for

many years. In the United States, cotton is usually measured with bales that

weigh about 0.48 cubic meters and weigh 226.8 kilograms.

b.

Jute fiber: Jute

is a long, soft, shiny bust fiber that can be cut into thick, strong threads.

It is originally produced from a plant of the genus Corchorus, which was once

classified with the Tiliaceae family. The primary source of fiber is the

Corchorus olitorius, but it is thought to be inferior to the Corchorus

capsularis. Jute is the plant fiber that is used to make burlap, hessian or

gunny cloth.

Jute

is one of the most affordable natural fibers, and second only to cotton in

quantity and variety used. Jute fibers are mainly composed of plant materials

cellulose and lignin. It falls into the category of bast fiber collected from

bust fiber plants with kenaf, industrial horn, flax (linen), rummy, etc., The

industrial term for jute fiber is raw jute fibers are white-brown and 1-4 m

tall. Jute is also called golden fiber for its color and high cash quality.

Jute

plants require simple alluvial soil and standing water. The climate is suitable for

growing jute (warm and wet) is presented during the rainy season by the monsoon

climate. Temperature 20˚C to 40˚C and relative humidity 70% to 80% Optimal

Cultivation for successful cultivation Jute requires 5-6 cm weekly rainfall at

the time of sowing and more. Soft water is required for jute production.

c.

Hemp fiber: Hemp

is a variety of cannabis Sativa plant species that are grown specifically for

the industrial use of its products. It is one of the fastest-growing plants and

it was one of the first plants cut into usable fibers 50,000 years ago. It can

be modified into various commercial items including paper, textiles, clothing,

biodegradable plastics, paints, insulation, biofuels, food, and animal feed.

Although

both cannabis and industrial hemp as drugs originate from the cannabis Sativa

species and contain the psychoactive ingredient tetrahydrocannabinol (THC),

they have different strains with different phytochemical compositions and uses.

Hemp has a lower concentration of THC and a higher concentration of cannabidiol

(CBD), which reduces or eliminates its psychological effects. The legitimacy of

industrial horns varies greatly between countries. Some governments control the

concentration of THC and only allow hemp that is bred with a particularly low

THC content.

d.

Sisal fiber: Sisal

is a species of Agave sisalana in South America with the botanical name but is

widely cultivated and naturalized in many other countries. It gives a solid

fiber yield used in making various products. The term sisal can refer to the

common name or fiber of a plant, depending on the context. It is sometimes

referred to as sisal hemp because hemp has been the main source of fiber for

centuries and other fiber sources have been named after it.

Sisal

fiber is generally used for rope and yarn and has many more uses including

paper, cloth, footwear, hats, bags, carpets, geotextiles, and dartboards. It is

used as a fiber reinforcement for composite fiberglass, rubber, and cement

products.

3.

Mineral fiber: Used

for asbestos and basalt fiber vinyl tiles, sheeting and adhesive, transit

panels and siding, acoustic ceilings, stage curtains, and fire blankets.

a.

Glass fiber: It

is used in the manufacture of an ironing board and mattress cover, rope and

cables, composite materials, insect nets, flame-retardant, and protective

fabric, and soundproof, fireproof, and insulating fibers. Glass fibers are

woven and coated with Teflon to make beta fabrics, a virtual fireproof fabric

that replaces nylon on the outer layer of the U.S. space suite since 1968.

b.

Metallic fiber: Metal

fibers are fibers made of metal, metal alloys, plastic-coated metals, fibers

made with a core completely covered by metallic-coated plastic or metal. As a

source of textile and garment applications, gold and silver fibers have been

used as yarn for fabric decoration since ancient times. Most recently, aluminum

yarn, aluminized plastic yarn, and aluminized nylon yarns have been replaced by

gold and silver.

|

| Metallic Fibre |

Today's metallic fiber industry mainly supplies fiber in stainless steel, nickel,

titanium, copper, and aluminum for various applications. Metal filaments can be

coated with a transparent film to reduce damage. Metal fibers can also be shaved

from wire (steel wool), shaved from foil, bundles are drawn from a wire of large

diameter, mixed from a knot, cast from molten metal, or grown around a seed

(usually carbon). There is a wide variety of uses for metal fibers, metal foil, and metal wire, including the manufacture of gold fabrics and jewelry. Hardware

cloth (US term only) is a thick woven mesh of steel wire, which is used in

construction. It's a lot like standard window screening but heavier and more

open-weaved.

c.

Minerals and natural: Minerals

and natural and synthetic fabrics can be mixed Like emery fabrics, a layer of

emery abrasive sticks to the back of the fabric. Also, the American term sand

cloth is a fine wire mesh that is used as emery cloth or coarse sandpaper.

4. Synthetic

fiber: The fiber we make from different types of chemicals like polyester, acrylic, and

nylon is called synthetic fiber. Synthetic fibers are primarily used in garment

manufacturing, as well as in making geotextiles.

a.

Polyester: Polyester

is a division of polymers that contains the ester functional group in their

main chain. As a specific ingredient, it refers to a type called polyethylene

terephthalate (PET). Polyesters include naturally occurring chemicals such as

tree cuttings, as well as synthetics such as polybutyrate. Natural polyesters

and a few synthetics are biodegradable, but most synthetic polyesters are not.

Material clothing is widely used.

|

| Polyester Fibre |

Polyester

fibers are sometimes cut together with natural fibers to form a fabric with

blended properties. Cotton-polyester blends can be strong, wrinkle, and

tear-resistant and reduce shrinkage. Synthetic fibers using polyester have

higher water, wind, and environmental resistance than plant-derived fibers.

These are less fire-resistant and can melt when ignited. Polyester blends have

been renamed to suggest their similarity or even superiority with natural

fibers. Liquid crystal polyester is one of the first liquid crystal polymers

used in the industry. These are used for their mechanical properties and heat resistance. These properties are important in their application as corrosive seals in jet engines.

b.

Nylon: The fiber used in imitation of nylon silk; is also used in the manufacture of

pantyhose. Thick nylon fibers are used in rope and outdoor clothing. Nylon is a

generic title for a family of man-made polymers based on aliphatic or

semi-perfumed polyamides. Nylon is a thermoplastic silky material that can be

melted-processed into fibers, films, or shapes. It is composed of repeating

units linked by amide links similar to the peptide bonds of proteins. Nylon

polymers can be mixed with a variety of additives to achieve a wide variety of

properties. Nylon polymers have found significant commercial applications in

fabrics and fibers (reinforcement of clothing, flooring, and rubber), in shapes

(molded parts for cars, electrical equipment, etc.), and in films (for most

food packaging).

Nylon

was first commercially used on nylon-bristled toothbrushes in 1938, followed

more popularly by women's stockings or nylon, which appeared at the New York World's

Fair in 1939 and was first commercially sold in 1940. During World War II,

almost all nylon production was a parachute, and the army was diverted to use

parachute cords. The use of nylon and other plastics during the war greatly

increased the market for new materials.

c.

Aramid: Aramid

fibers are heat-resistant and strong synthetic fibers. They are used in space

and military applications for ballistic-rated body arm fabrics and ballistic

composites, marine cordage, marine whole reinforcement, and asbestos alternatives.

The chain molecules in a Portmanteau fiber of the name aromatic polyamide are

highly illuminated along the axis of the fiber. As a result, a higher ratio of

chemical bonds contributes more to fiber strength than many other synthetic

fibers. It has a very high melting point (> 500 °C).

d. Acrylic: Acrylic

is a fiber used to imitate wool, including cashmere, and is often used in

substitution. Acrylic fibers are synthetic fibers from a polymer

(polyacrylonitrile) with an average weight of about 1, 00000, and about 1900

monomer units on average. In the United States, a fiber can be called acrylic,

the polymer must contain at least 85% acrylonitrile monomer. Common comonomers

are vinyl acetate or methyl acrylate. DuPont made the first acrylic fibers in

1941 and trademarked them under the name Orlon. It was first developed in the

mid-1940s but was not mass-produced until the 1950s. Strong and warm, acrylic

fiber is often used for sweaters and tracksuits and for lining boots and

gloves, as well as in fabrics and carpets. It is produced as a filament, then

cut into short major lengths like wool hair and cut with yarn.

Modacrylic

is a modified acrylic fiber that contains a minimum of 35% and a maximum of 85%

acrylonitrile monomer. The commoner used in modacrylic is vinyl chloride,

vinylidene chloride, or vinyl bromide fiber flame retardant properties.

Modacrylic end-uses include fax wool, wigs, hair extensions, and protective

clothing.

e.

Spandex: Spandex,

Lycra, or elastane is a synthetic fiber that is known for its exceptional

elasticity. It is a polyether-polyurea copolymer that was discovered in 1958 by

chemist Joseph Shiver at DuPont’s Benger Laboratory in Waynesboro, Virginia.

Spandex is a polyurethane product that can be tightly fitted without

obstruction. It is used to produce activewear, bras, and swimsuits.

f. Olefin: Olefin

fiber is a synthetic fiber made from polyolefins, such as polypropylene or

polyethylene. The official definition of olefin fiber by the Federal Trade commission is manufactured fiber where the fiber is made of a long-chain synthetic polymer that is made up of at least 85% by weight of ethylene,

propylene, or other olefin units and Car interior. The advantages of olefin

fibers are their strength, colorlessness, comfort, staining, tearing,

abrasion, and resistance to sunlight, and their good bulk and cover. Olefin fiber

is a fiber used in activewear, lining, and warm clothing. Olefins are

hydrophobic, allowing them to dry quickly. A soothing feeling of olefin fibers

is sold under the name Tyvek.

g. Milk fiber: Milk

proteins have also been used to make synthetic fabrics. Milk or casein fiber

cloth was further developed in Germany during the First World War and in Italy

and America in the 1930s. Milk fiber fabric is not very durable and easily

wrinkles but it has the same pH as human skin and has anti-bacterial

properties. It is marketed as a biodegradable, renewable synthetic fiber.

h.

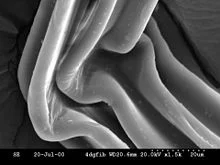

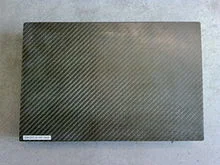

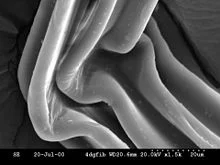

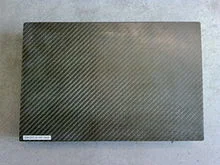

Carbon fiber: It

is used in most blended materials, such as carbon fiber-reinforced plastics

together with resin. Fibers are made from polymer fibers through carbonization.

Carbon fibers are used to fabricate microelectrodes of carbon fiber. In this

application, a single carbon fiber 5-7 mm in diameter is usually sealed in a

glass capillary. At the tip, the capillary is either sealed with epoxy, and a

carbon-fiber disc is made to form the microelectrode, or the fiber is cut to a

length of 75-150 mm to form the carbon-fiber cylinder electrode. Carbon-fiber

microelectrodes are used in amperometry or fast-scan cyclic voltmeters for

biochemical signal detection.

|

| Carbon Fibre |

0 Comments