Fabric softener

A fabric softener is a conditioner that is usually washed in a washing machine and applied to the laundry during the cycle. Unlike laundry detergents, fabric softeners can be considered a laundry aid after treatment. Similar to a wrap release and more thin preparation is meant to be sprayed directly on the fabric.

Properties of softener

1.

Fabric softener is synthetically made from a chemical compound.

2.

It is designed to coat the fabric and remains there.

3.

It can be skin irritating and linked with dermatitis, particularly with repeated exposure.

4.

Its main ingredients are quaternary ammonium compounds

5.

Usually, fabric softener decreases the absorbency of the fabric.

6.

It has a synthetic fragrance.

7.

Its overuse can make the fabric more flammable.

8.

It increases fabric strength.

Softener Mechanism

Machine

washing puts a lot of mechanical stress on textiles, especially natural fibers

such as cotton and wool. The fibers on the fabric surface squash and burn and

make the laundry feel stiff when air-dried. The final wash adds a soft fabric

softener to make the laundry feel softer.

In the United States and the United Kingdom, laundry is mostly dried in a mechanical dryer, and dryer tumbling with laundry has its own softening effect. Therefore, fabric softeners in the United States and the United Kingdom have rather antistatic properties and provide a nice smell in laundries. Fabric softeners are usually in liquid form, which are added to the washing machine during the washing cycle; Or as a dryer sheet that is added to the wet laundry at the beginning of the drying cycle. Liquid fabric softeners can be designed for this purpose during the washing cycle or automatically on the machine.

It covers the surface of a fabric with chemical compounds that are electrically charged, causing the threads to rise from the surface and give a soft and fluffy texture. Cationic softeners are bound by negatively attracted electrons to the negatively charged groups on the surface of the fibers and neutralize their charge. The long aliphatic chains then move to the outside of the fiber, giving off oiliness.

Softener nature

Early

cotton softeners were usually based on a water mixture of soap and olive oil,

corn oil, or tallow oil. Softening compounds are similar to different fabrics.

Some work better on cellulose-based fibers, while others use hydrophobic

substances such as nylon, polyethylene terephthalate, polyacrylonitrile, etc.

New silicone-based compounds like polydimethylsiloxane are worked as

lubricating the fibers. Manufacturers also use derivatives with amine- or

amide-containing functional groups. These groups improve the binding of

softeners to fabrics.

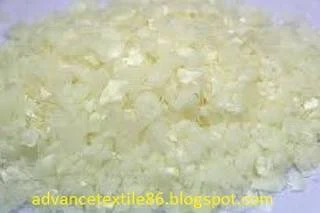

Since softeners are often hydrophobic, they usually occur in the form of emulsions. In the early formulas, manufacturers used soap as an amplifier. Emulsions are usually opaque, milky liquids. However, there are also microemulsions, where the hydrophobic phase droplets are small enough. Tiny particles facilitate the increased efficiency of tiny particles entering the fiber. Manufacturers often use a mixture of cationic and non-ionic surfactants as emulsifiers. Another method is a polymeric network, an emulsion polymer. Fabric softening chemicals may include silicone-based anti-foaming agents, emulsion stabilizers, perfumes, and dyes to maintain optimal pH for absorption in fabric softeners.

Type of softener

1.

Cationic softener

2.

Anionic softener

3.

Non-ionic softener

4.

Antiozone softener

5. Amphoteric softener

6. Silicon softener

Cationic softener

Rinse-cycle

softeners generally contain quaternary ammonium-type cationic surfactant as the

active ingredient. Cationic surfactants adhere well to natural fibers but less

so to synthetic fibers. Cationic softeners are incompatible with anionic

surfactants in detergents because they combine with them to form solid

precipitation. For this, you need to add a softener to the rinse cycle. Fabric softeners reduce the absorption of textiles, which adversely affects the

function of towels and microfiber fabrics.

Anionic softener

Anionic

softeners and antistatic agents, for example, maybe the salts of

monounsaturated and dieters of phosphoric acid and fatty alcohols. These are

often used in conjunction with conventional cationic softeners. Cationic

softeners are incompatible with anionic surfactants in detergents because they

combine with them to form solid precipitation. For this, they need to be washed

and added to the cycle. Anionic softeners can combine directly with an anionic

surfactant. Other anionic softeners can be made based on Smectite Clay. Many

compounds like ethoxylated phosphate esters have softening, anti-static, and

surfactant properties.

Conclusion

Before unloading the fabric all-time softener is used for fabric softening. A maximum time cationic softener is used, sometimes another softener is used. If need shade changes cationic softener is used, for white garments only non-ionic softener is used.

0 Comments