Polymers

Polymers

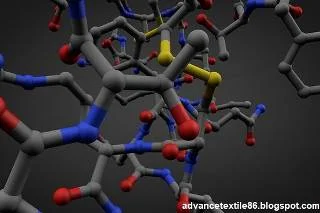

are a class of natural or synthetic substances composed of very large molecules

called macromolecules that are multiples of the common chemical unit known as

monomers. Polymers make up many materials for living organisms, for example, proteins,

cellulose, and nucleic acids.

The

term polymer determines an indefinite number of monomer units. When the number

of monomers is too high, the compound is called a high polymer. Polymers are

not limited to the same chemical composition or molecular weight and structure

monomer. Some natural polymers are composed of a type of monomer. The most

natural and synthetic polymers are composed of two or more different types of

monomers and these polymers are known as copolymers.

Synthetic polymers are produced by a variety of reactions. Many common hydrocarbons, like

ethylene and propylene, can be converted into polymers by adding one monomer

after another to the growing chain. Polyethylene is composed of recycled

ethylene monomers, is an additive polymer. It can join about 10,000 monomers in

a long-coiled chain.

Different types of polymers are mixed organic-inorganic compounds. The most important representative of this polymer family is silicon. The backbone of them consists of silicon and oxygen atoms with the biological group attached to each silicon atom. Silicone with low molecular weight is oil and grease. Oils and greases are low molecular-weight silicones.

Properties of polymers

i.

Heat conductivity - the amount of plastic or polymer that acts as an effective

insulator against the flow of heat. Polystyrene polymer in disposable plastic

glasses is not a very good insulator. However, the airflow through the styrene

during polymerization gives the Styrofoam used for disposable coffee cups which

is used as a better insulator.

ii.

Crystallization - the number of polymer chains arranged in a regular structure

rather than in a random fashion. Some polymers, like Silly putty and Play

Dough, lack the inertia needed to make very amorphous and useful products.

Polymers that are very crystalline are often very fragile.

iii.

Permeability - Permeability of polymer means the tendency of polymers to

extruded materials. Polythene is used to wrap food because it is 4000 times

less permeable to oxygen than polystyrene.

iv.

Tensile strength - When chain length and cross-linking increase, then the

tensile strength of the polymer increases.

v.

States of polymers - polymers have different states such as partially

crystalline state, viscoelastic state, highly elastic state, and glassy state.

vi.

Young's modulus of elasticity - It quantifies the elasticity of the polymer. It

is highly relevant in polymer applications like the physical properties of

polymers. The modulus strongly depends on temperature.

vii.

Flexibility - Flexibility in molecular chains makes polymer components very

flexible. The flexibility of the polymer is enhanced by the molecular

properties that inhibit the branching order.

viii.

Transport properties – It describes how molecules move rapidly through the

polymer matrix. Many applications of polymers for film and membranes make it

very important.

ix.

Chemical properties - The attractive forces within the polymer chain play a

major role in determining the properties of the polymer. The intermolecular

forces in polymers can be affected by dipoles in monomer units. Polymers with

amide or carbonyl groups can form hydrogen bonds between adjacent chains;

Partially positively charged hydrogen atoms in the N-H groups of a chain are

strongly attracted to partially charged oxygen atoms in the C = O groups.

x.

Optical properties - These polymers have a high quality and are extremely

transparent so that the laser properties are dominated by the laser dye used to

dope the polymer matrix. An important optical parameter of polymers used in

laser applications is the change of reflective indicators known as DN / DT with

temperature.

Types of polymers

i. Natural polymers.

ii. Synthetic polymers.

iii. Addition polymers.

iv. Condensing polymers.

v. Rearrangement polymers.

vi. Biodegradable polymers.

Natural polymers

Natural polymers are defined as materials that occur extensively in nature or are extracted from plants or animals. Natural polymers are essential for everyday life because our human forms are based on them. Some examples of natural polymers are proteins and nucleic acids that occur in the human body, cellulose, natural rubber, silk, and wool. Starch is a natural polymer made up of hundreds of glucose molecules, similarly, natural rubber is a polymer derived from the latex of a rubber plant. Honey is another example of naturally occurring polymers that are used significantly in everyday life.

Synthetic polymers

The list of synthetic polymers includes polyethylene, polypropylene, polystyrene, polyvinyl chloride, synthetic rubber, phenol-formaldehyde resin, neoprene, nylon, polyacrylonitrile, some more, and PVB, according to the global demand. More than 330 million tons of these polymers are produced each year. At most, the polymer used to make plastics consists mainly of carbon atoms in the continuously attached spine. A simple example is polythene, the repeating unit of which is based on ethylene monomer. Many other structures exist; For example, materials such as silicone make known materials such as silicone, for example, silicone putty, and waterproof plumbing sealant. Polymer backbones also typically contain oxygen, such as polyethylene glycol, polysaccharides, and DNA.

Addition polymers

An addition polymer is a polymer that forms by simply attaching monomers without the co-generation of other products. Addition polymerization differs from condensation polymerization, which is a product, usually co-produced by water. Addition polymers may be formed by chain polymerization when the polymer is formed by increasing the addition of monomer units at the active site in a chain reaction, or by polymerization when polymers are formed by additional reaction between species of all degrees of polymerization. Addition polymers are formed by the repeated addition of some common monomer units. Polymers are usually unsaturated compounds such as alkenes, alkalines, etc. The free radical mechanism of additional polymerization is accomplished in three steps i.e. initiation of free radical, chain propagation, and chain termination.

Condensation polymer

Condensation polymer is a type of polymer that is formed by a condensation reaction, where molecules come together, then lose tiny molecules as by-products such as water or methanol. Polymers are formed by a condensation reaction in species of all degrees of polymerization when polymers are formed by polymerization, or when polymers are formed by sequential addition of monomers at an active site in a chain reaction. The main alternative forms of polymerization are chain polymerization and polyaddition, both of which give additional polymer. Condensation polymerization is a form of step-growth polymerization. Linear polymers are produced from bi-functional monomers, such as compounds of two reactive end groups. Common condensing polymers include polyamide, polyacetal, and proteins.

Biodegradable polymers

Biodegradable polymers are a special class of polymers that break down bacteria for their intended purpose through the process of decomposition to produce natural by-products such as gas (CO2, N2), water, organic matter, and inorganic salts. These polymers are available in both natural and synthetic formulations and consist mainly of the functional groups of esters, amides, and ethers. Their properties and the process of breakdown are determined by their exact structure. These polymers are synthesized by frequent condensation reactions, ring-opening polymerization, and metallic catalysts. There are extensive examples and applications of biodegradable polymers. Organic-based packaging materials have been introduced as green alternatives in recent decades, with edible films gaining more attention due to their eco-friendly properties, wide variety and availability, non-toxicity, and low cost.

Uses of polymers

i.

A polymer such as polypropylene explores its use in a wide range of industries

like textiles, packaging, stationery, plastics, aircraft, construction, rope,

toys, etc.

ii.

Polymer-like polystyrene is one of the most common plastics that is actively

used in the packaging industry. It is used to make bottles, toys, containers,

trays, disposable glasses and plates, TV cabinets, and lids are some of the

everyday products. Polystyrene is also used as an insulator.

iii.

The most important use of polyvinyl chloride in making sewer pipes. It is also

used as an insulator in electrical cables like Polystyrene.

iv.

Polyvinyl chloride polymer is used for clothing and furniture and has recently

become popular for the construction of doors and windows. It is also used in a

kind of plastic floor.

v.

Urea-formaldehyde polymer resins are used to make adhesives, molds, laminated

sheets, integral containers, etc.

vi.

Glyptal polymer is used to make paints, coatings, and varnishes.

vii.

Bakelite polymers are used to make electric switches, kitchen products, toys,

jewelry, firearms, insulators, computer discs, etc.

0 Comments