Plain weave

Of

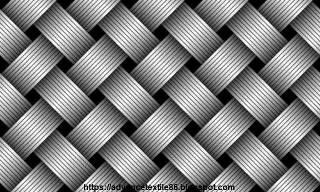

the three basic types of textile weaving, plain weave is the most basic. It is

a strong and tough wearer and is used for fashion and upholstery fabrics. This

is done by placing each filling yarn over each warp yarn and making each row

alternately, making a higher number of intersections. There is no right or

wrong side to plain-weave fabric that is not printed or given a surface finish.

They do not rotate easily but tend to shrink and absorb less than other looms. In

plain weave fabric, the warp and weft threads cross at right angles, lining up

so that they form a simple criss-cross pattern. Each weft thread crosses the

warp threads one on top of the other, then the bottom of the next, and much

more. The next weft thread goes under the warp thread which goes to its

neighbor and vice versa.

The

visual effects of plain weave can be varied by combining yarns of different

origins, thicknesses, textures, twists, or colors. Fabrics weigh from sheer to

heavy and include types such as organdy, muslin, taffeta, shantung, canvas, and

tweed. Variations of plain weave include ribbed weave, in which the rib or fill

yarn is heavier, as in dimity and Bengaline, and basket weave so that two or

more filling yarns or one heavy yarn go down two or more warp yarn, such as

oxford shorts and monk's clothing.

Plain weave history

The

earliest evidence of human use of cloth is from colored flax fiber found in a

cave in the Republic of Georgia, dating to 34,000 BC. In this case, flax fibers

were used to make a kind of felt fabric. The earliest evidence of weaving dates

27,000 years ago and was found in Dolni Vestonis in the Czech Republic in the

form of textile and basket impressions and mesh in small pieces of hard clay.

The first example of nålebinding, a kind of single-needle knitting without

knots, dates back to 6500 BC. There are three basic types of textiles: plain

weave, twill, and satin.

Plain weave fabric properties

i.

Plain weave is the simplest and most used weave

ii.

It is found in a wide range of fabrics such as gauze, gingham, taffeta, poplin,

and canvas.

iii.

It requires only two hardness because the weave repeats every two ends

iv.

It has lower rear strength than others because when tearing a plain weave fabric,

the yarn breaks one at a time.

v.

It has the maximum number of binding points

vi.

The threads interlace in an alternate order of 1 up and 1 down.

vii.

The thread density is limited

viii.

Cloth thickness and mass per unit area are limited.

ix.

It produces a relatively stronger fabric that is obtained by any other simple

combination of threads, except that of “gauze” or “cross weaving”.

x.

It has no right or wrong side.

xi.

It has no lengthwise or crosswise stretch, the only stretch is on the bias.

xii.

It doesn't fray as easily as other weaves.

xiii.

It creases easily.

xiv.

Less absorbent than other weaves.

xv.

Fabrics range in weight from sheer to heavy, depending on the yarns used.

xvi.

It is versatile.

xvii.

It is flexible.

Plain weave fabric description

Plain weaving requires only two harnesses and each weave unit has two warp and weft yarns. To make it, the warp yarns are held parallel under tension while a horizontal weft yarn is shot over and below the alternate warp across the width of the web. The weaving unit is completed at the end of the second row, when the weft is inserted over and under the opposite set of warps, thus locking the previous weft in place. The length of the fabric is increased with each subsequent weft yarn insert. When warp and weft yarns are about the same size and quantity, the finished fabric is more balanced and potentially stronger than fabrics made with the same type of fabric, and the number of warp and weft yarns in any other basic weave. The tabby woven with warp and weft yarns of various sizes, produces fabrics such as taffeta and poplin, whereas many fine warp yarns are woven with proportionately less thick yarn or ribs. The term extended tabby refers to a weave where two or more warps or wefts, or both, are joined together as a single unit. This group includes fabrics with the effect of baskets and fabrics with ribs formed by a team of warps or wefts in each shed. Tapestry weave is a tabby in which patterns are made by tying yarns of different colors. It is usually an unbalanced weave, the wefts of which cover a relatively small number of warps completely. These fabrics are stiff and compact. Although they are flat and do not usually drape well, they have been used in making formal and decorative garments and costumes.

Plain weave types

A.

Muslin: Muslin is a loosely-woven cotton fabric that is made using plain weave

techniques, which means that a single weft thread alternates between a single

warp thread over and under. It is known as the material used in fashion

prototypes to test the pattern before cutting and sewing the final product.

B.

Buckram: Buckram is a plain-woven fabric that can be woven loosely or tightly.

The hard, thick material is most commonly used inside baseball caps.

C.

Cheesecloth: Cheesecloth fabric is a plain-weave fabric that Chefs use as a

tool in making cheese. The loose weave of the fabric allows the liquid to

strain easily through it.

D.

Flannel: This loose weave fabric can be made using plain or twill weaves. The

flannel is often brushed on one or both sides to enhance the fine fiber and

make it feel softer.

E.

Chiffon: Chiffon is a plain weave fabric that is thin, airy, and sheer. Sheer

fabrics can be woven from both synthetic and natural textiles such as silk,

nylon, rayon, or polyester.

F.

Organdy: Organdy is a delicate, simple, woven fabric that is woven from cotton.

Crispy, lightweight material is often used in the line of bridal gowns, evening

dresses, veils, and aprons.

G.

Poplin: It is a plain weave fabric with very fine warp yarn and thick weft

yarn. This fabric is very light, with a light, airy drape.

H.

Chambray: Chambray is a plain weave fabric where warp threads are usually dyed

blue and weft is not dyed, giving it a blue look like denim.

I.

Velvet: Velvet is made on a special loom known as a double cloth, which

simultaneously makes two pieces of velvet. This luxurious fabric can be woven

into any weave structure (plain, satin, or twill) with an extra set of warp

threads that are spun to create a softer feel.

J.

Taffeta: This fabric is made using the plain weave technique, which has a

single weft thread and goes under a single warp thread, creating a checkerboard

pattern. In making taffeta, the threads are twisted as they are woven, which in

turn creates the firmness and structure of the fabric.

K.

Organza: Organza is a lightweight, sheer, plain woven fabric originally made

from silk. The material can also be made from synthetic fibers, primarily

polyester, and nylon.

L.

Crepe: This fabric can be woven from any weaving structure. It has a rough,

irregular structure due to the especially twisted or crimped yarn. The

materials used to make crepe and the methods used to obtain the texture define

different types of crepe.

M.

Georgette: Georgette is a plain weave fabric woven using tightly twisted

S-twist and Z-twist yarns, which are twisted yarn on opposite sides. These

twists create a slight puffiness on the surface of the fabric, giving Georgette

her signature crinkled finish.

N. Cambric: This fabric is a finely woven plain-weave fabric that is rolled and flattened at high temperatures to create a smooth finish.

0 Comments